Blog > Concrete Creations & Excavations Articles

Concrete Creations & Excavations Article Library

Welcome to the Concrete Creations & Excavations Blog Article Library, a valuable resource designed to connect homeowners like you with the world of concrete craftsmanship and innovation. Our blog serves as a hub for those seeking inspiration and information about the remarkable potential of concrete in transforming your living spaces. Whether you're planning a home improvement project, considering a renovation, or simply intrigued by the beauty of concrete, our library of articles is here to empower you with knowledge and insights. Join us on a journey of exploration as we unveil the incredible possibilities of concrete and showcase the exceptional creations that await you. At Concrete Creations & Excavations, we're not just a contractor; we're your partner in creating concrete masterpieces that enhance your home's beauty and functionality.

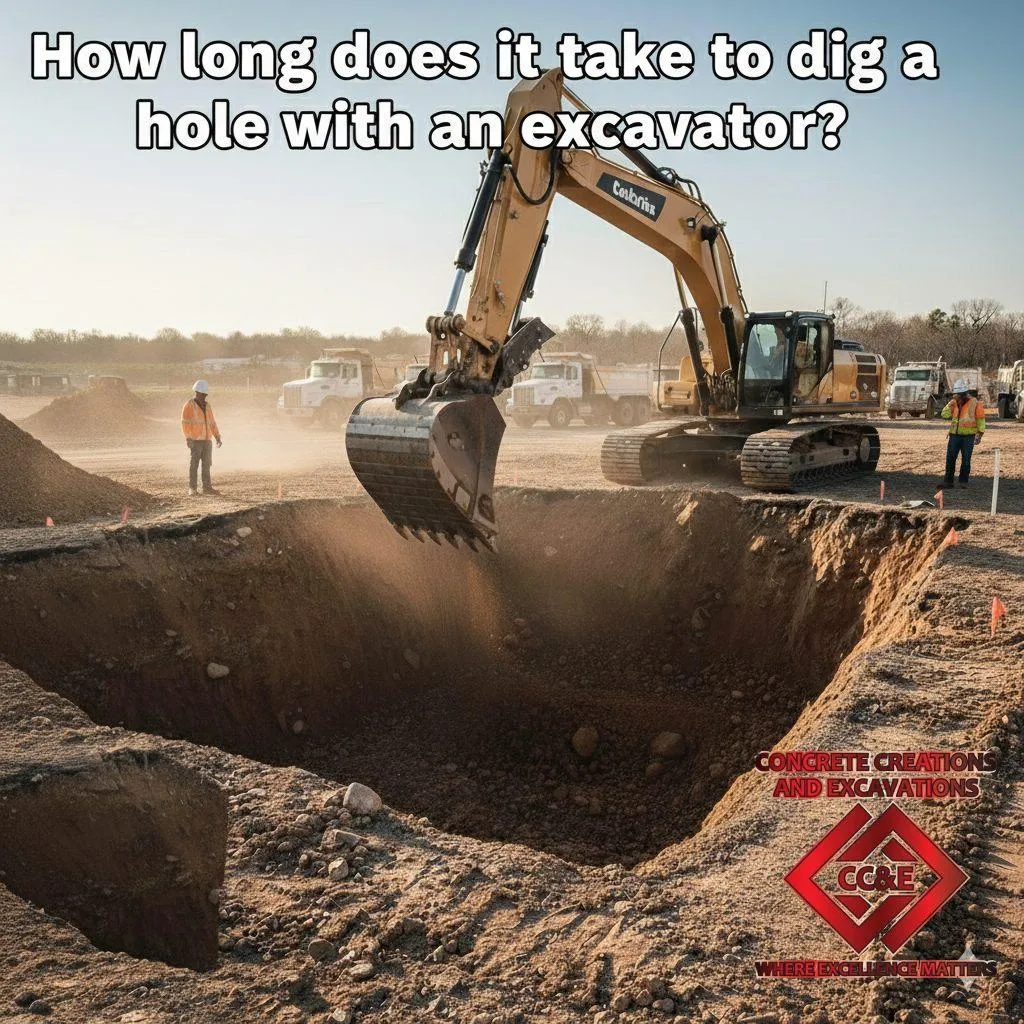

How long does it take to dig a hole with an excavator?

Digging a hole with an excavator is a critical task in construction, landscaping, and infrastructure projects, but the time required can vary significantly due to a multitude of influencing factors. Variables such as the size and depth of the hole, soil composition, type of excavator used, operator skill, and external conditions like weather all play pivotal roles in determining the duration of the task.

This comprehensive guide explores these elements in detail, providing actionable insights for homeowners, contractors, and project managers to plan their excavation projects effectively, while emphasizing the value of professional services like those offered by Concrete Creations & Excavations in Northwest Arkansas.

Excavators are powerful machines that transform digging from a labor-intensive process into a swift, mechanical operation, capable of completing in hours what might take days or weeks manually.

Understanding the interplay of equipment capabilities and site-specific challenges is essential for setting realistic timelines and budgets. Whether you're excavating for a residential pool, a commercial building foundation, or a utility trench, this article will help you anticipate the time required and make informed decisions to ensure project success.

Understanding Excavators

Excavators are robust, versatile machines designed for digging, lifting, and moving earth, featuring a boom, dipper, bucket, and rotating cab mounted on a base of tracks or wheels. Their efficiency stems from advanced hydraulic systems that enable precise, powerful movements across a wide range of terrains and materials.

Selecting the appropriate excavator type and size is crucial, as it directly influences digging speed, project feasibility, and overall efficiency, whether working in confined residential spaces or expansive commercial sites.

Types of Excavators and Their Capabilities

Crawler excavators, equipped with tracks for superior traction, are ideal for uneven or soft terrain, such as construction sites with loose soil or rocky ground. They excel in deep excavations, like those for building foundations, where their stability prevents tipping under heavy loads, allowing for rapid material removal in favorable conditions.

Wheeled excavators, designed for mobility on flat or paved surfaces, are well-suited for urban projects where quick repositioning between digging sites is necessary, reducing setup time and enhancing productivity.

Mini excavators, compact and weighing under ten tons, are perfect for residential tasks like digging utility trenches or small ponds, often completing these jobs in just a few hours due to their agility in tight spaces. Zero-tail-swing models minimize space requirements, making them ideal for backyards or areas near existing structures, preventing damage while maintaining efficiency.

Dragline excavators, used for large-scale projects like mining or deep pond excavation, utilize a long boom and drag bucket to move massive volumes of earth, though their complex setup can extend initial timelines. These are less common in standard construction but invaluable for large, deep holes.

Long-reach excavators, with arms extending significantly, are designed for digging in hard-to-access areas like wetlands or over obstacles, though their extended hydraulics may slightly slow cycle times due to the increased mechanical complexity.

Suction or vacuum excavators employ air or water jets for precise, non-destructive digging around utilities, prioritizing safety in sensitive areas, though this precision often comes at the cost of slower progress. Skid-steer excavators combine loader functionality with digging attachments, offering versatility for projects requiring both excavation and material spreading, making them ideal for multi-task sites.

Hydraulic shovels, built for heavy-duty tasks like mining, provide exceptional digging force but may operate more slowly in confined spaces compared to standard excavators. Short swing radius excavators reduce tail swing, enabling efficient work near walls, fences, or traffic, which speeds up urban digging by minimizing the need for constant repositioning.

Each excavator type’s capabilities, from bucket capacity to engine power, directly affect how quickly a hole can be dug, underscoring the importance of matching the machine to the project’s specific requirements.

How Excavator Size Influences Digging Speed

Mini excavators, lightweight and highly maneuverable, are designed for small holes, such as those for landscaping features or residential utility lines, completing these tasks in a few hours due to their quick cycle times in confined spaces.

They are ideal for homeowner projects where space is limited, efficiently handling moderate earth volumes daily. Mid-sized excavators, typically in the medium-weight range, enhance efficiency for commercial tasks, capable of moving larger quantities of material daily and reducing the number of passes needed for medium-sized holes, significantly shortening project timelines.

Large excavators, built for major digs like expansive foundation pits or commercial site preparations, can complete excavation over several days, including ancillary tasks like debris removal or site leveling.

Their sizable buckets allow for high output, but they require more fuel and skilled operators to maximize efficiency. The size of the excavator impacts cycle time; smaller machines complete scoops quickly due to their compact design, while larger ones take longer per cycle because of their greater reach and load capacity. Advanced hydraulic systems in newer models minimize delays by enabling faster boom and bucket movements.

Operator familiarity with the excavator’s size is critical; inexperienced operators may struggle with larger machines, leading to slower progress, while skilled operators can optimize movements to achieve faster completion times. Terrain compatibility also plays a role—compact excavators perform best in soft, confined areas, while larger models excel in open, hard ground excavations, where their power can be fully utilized.

Factors Affecting Digging Time

Numerous factors converge to determine how long it takes to dig a hole with an excavator, encompassing natural site characteristics, equipment performance, operator expertise, and external conditions.

Soil composition can drastically alter timelines, while weather and site accessibility introduce variables that can delay progress. Thorough pre-site assessments and strategic planning are essential to minimize these challenges and keep projects on track.

Soil Conditions and Their Impact

Loamy or sandy soils are ideal for rapid digging, allowing excavators to move through material quickly, particularly for linear tasks like trenches. These loose soils fill buckets efficiently, reducing cycle times and enabling faster progress.

Clay-heavy soils, however, are dense and sticky, resisting bucket penetration and requiring slower operations or specialized attachments like toothed buckets, which can significantly extend daily work durations. Rocky terrains pose another challenge, often necessitating hydraulic breakers to fragment material before removal, adding hours to the process.

The presence of groundwater complicates excavations, requiring dewatering pumps that halt digging for setup and ongoing management, potentially extending deep hole projects by days.

Soil testing through borings or geotechnical surveys can predict these issues, guiding the selection of appropriate equipment and attachments to mitigate delays. Particle size also influences efficiency; finer soils compact less, speeding up digging but potentially compromising wall stability, which may require additional stabilization measures.

Hole Size and Depth Considerations

Shallow holes, such as those for landscaping features or shallow utility lines, can often be completed in a matter of hours, especially with compact excavators designed for quick work in small areas.

Deeper excavations, particularly those exceeding significant depths, require shoring or sloping to prevent collapses, which can stretch timelines into weeks due to the need for careful, staged digging.

Calculating the volume of material to be removed is critical for estimating time—a modestly sized hole might be completed in a single day with a mid-sized excavator under good conditions.

Wider holes necessitate more passes, increasing the time required, though strategic sectional digging can optimize the process by focusing on smaller, manageable areas.

Complex hole shapes, such as those for irregularly designed pools, demand greater precision, adding time compared to straightforward rectangular excavations like those for building foundations.

Operator Experience and Machine Efficiency

Experienced operators significantly enhance productivity, maximizing material movement through efficient loading, swinging, and dumping techniques.

Their ability to minimize idle time and optimize machine movements can substantially reduce project durations. In contrast, inexperienced operators may double timelines by using suboptimal angles, requiring frequent corrections, or mismanaging equipment settings.

Regular maintenance of the excavator ensures peak performance; issues like clogged filters, worn components, or low hydraulic fluid can slow cycle times noticeably, leading to delays. The layout of the site also affects efficiency—larger swing angles increase loading time, so careful planning to position the machine and spoil piles effectively can streamline operations. Training specific to the excavator model used enhances speed, transforming potentially lengthy jobs into quicker completions.

Weather and Site Accessibility

Adverse weather, particularly heavy rain, can transform sites into muddy quagmires, slowing machinery and necessitating drying periods that may delay work by days. Extreme temperatures, such as cold weather, can affect hydraulic systems by thickening fluids and reducing operational speed.

Site accessibility is another critical factor; narrow or obstructed paths limit the size of the excavator that can be used, often requiring additional manual preparation that extends timelines.

Urban environments with obstacles like overhead power lines or underground utilities demand cautious, slower digging to avoid damage, while remote sites may increase transport time for heavy equipment. Scheduling excavations during favorable seasons, such as avoiding peak rainy periods, helps maintain consistent progress and avoid weather-related setbacks.

Average Timelines for Common Excavation Projects

Establishing timelines for common excavation projects provides valuable benchmarks for setting expectations, with residential tasks typically faster than commercial ones due to differences in scale and complexity. Linear excavations like utility trenches can progress rapidly, while foundation digs vary depending on the structure’s size and site conditions.

Residential Projects: Pools and Foundations

Excavating a hole for a backyard pool, typically of moderate size, generally takes a few days, including time for shaping the hole and preparing for drainage systems. Foundation excavations for standard homes can range from a single day for simple slabs to a week for basements, which require deeper digging and additional inspections.

Soil stability significantly influences timelines; sandy soils allow for faster progress, while clay-heavy sites demand extra stabilization efforts, slowing the process.

Smaller residential projects, such as excavations for home additions or detached garages, may be completed quickly, often in a day, though delays from permitting or unexpected site conditions can extend timelines. Professional excavation contractors like Concrete Creations & Excavations enhance efficiency with advanced techniques, such as hydro digging, which ensures safety around utilities and minimizes disruptions.

Commercial and Infrastructure Digging

Commercial site preparations, such as those for building pads or large foundations, typically span one to two weeks, depending on the area and depth of the excavation. Infrastructure projects, like road bases or expansive pits for utilities, can take significantly longer, particularly when regulatory inspections or environmental considerations require phased approaches.

Deploying multiple excavators can reduce timelines by allowing simultaneous work on different sections, though this increases coordination demands.

Concrete companies that integrate excavation with subsequent tasks, like pouring foundations, can streamline overall project timelines by eliminating delays between contractors.

Landscaping and Utility Trenches

Trenching for utilities, such as irrigation lines or electrical conduits, achieves high hourly progress rates, often completing long runs in a single day with narrow buckets designed for precision. Landscaping features, like ponds or tree planting pits, may take only hours individually, but projects involving multiple features can accumulate to several days.

Hydro excavation methods, while slower, are often used for utility trenches to prevent damage to existing infrastructure, prioritizing safety over speed.

Comprehensive yard redesigns that include grading or leveling alongside digging may span several days, with interruptions from inclement weather being a common challenge.

Safety Considerations in Excavation

Safety is paramount in excavation projects to prevent accidents, with cave-ins being a primary concern that requires proactive measures. Regular inspections and the use of protective systems are mandatory for deeper excavations to ensure worker safety and project continuity.

Preventing Cave-Ins and Falls

Sloping trench walls at appropriate angles or installing shoring systems, such as trench boxes, prevents collapses, particularly in excavations exceeding shallow depths.

Providing safe entry and exit points, like ladders placed at regular intervals, ensures workers can evacuate quickly in emergencies. Keeping spoil piles and heavy equipment away from excavation edges avoids overloading, which could trigger collapses or falls.

Daily monitoring for signs of instability, such as cracks or water accumulation, halts work if conditions are unsafe, preventing accidents that could delay projects significantly.

Atmospheric and Utility Hazards

Testing for hazardous gases in confined or deep excavations is critical, using monitors to check oxygen levels and detect toxins, with ventilation systems employed if conditions are unsafe. Identifying underground utilities through services like 811 calls prevents accidental strikes, which could lead to dangerous gas leaks or electrical hazards.

Hydro excavation is often used near marked utility lines to minimize risks, requiring careful, slower digging within close proximity.Water accumulation from rain or groundwater increases slip and collapse risks, necessitating pumping systems to maintain a safe working environment.

Personal Protective Equipment and Training

Workers must wear appropriate gear, including hard hats, gloves, steel-toed boots, and high-visibility vests, to protect against falling debris and ensure visibility on busy sites. Comprehensive training on excavator operation, site hazards, and emergency procedures reduces the likelihood of accidents, minimizing delays. High-visibility barriers and signage cordon off excavation zones, enhancing safety for both workers and passersby.

Ongoing education about soil types, weather impacts, and equipment safety fosters a culture of vigilance, extending project timelines slightly but saving significant costs by avoiding accidents.

Costs Involved in Digging with an Excavator

Budgeting for an excavation project involves accounting for equipment rentals, labor, and additional expenses, with costs varying based on the excavator’s size and project scope. Operator fees and site-specific requirements further influence the total budget, making cost estimation a critical planning step.

Rental and Operational Expenses

Mini excavators are available for short-term rentals at relatively affordable rates, suitable for small residential projects, while larger models command higher daily costs, particularly for commercial or infrastructure digs.

Transporting excavators to the site adds to expenses, especially for remote locations where logistics are complex. Maintenance packages, often included in rental agreements, ensure equipment reliability, preventing costly downtime due to mechanical issues.

Fuel consumption is a significant factor, with mid-sized excavators using substantial amounts hourly, which must be factored into budgets for extended projects.

Project-Specific Costs

Permitting and regulatory inspections can add to costs, varying by project size and location. Disposing of excavated material incurs fees based on volume, particularly for projects requiring off-site hauling. Specialized attachments, such as hydraulic breakers for rocky soils, increase rental costs, impacting the overall budget. Small excavations may have modest total costs, while large-scale projects can escalate significantly due to cumulative expenses.

Engaging excavation services near you, like those provided by Concrete Creations & Excavations, often bundles these costs efficiently, leveraging expertise to optimize spending.

Value of Professional Services

Hiring professional excavation contractors eliminates the complexities of managing rentals and logistics, with firms like Concrete Creations & Excavations offering comprehensive solutions at competitive rates. With extensive experience in Northwest Arkansas, they ensure efficient, cost-effective excavations tailored to local conditions. Integrating concrete services post-excavation, such as pouring foundations or driveways, reduces costs by streamlining contractor coordination.

When to Hire a Professional Excavation Contractor

While DIY excavation may be feasible for small, shallow holes, professional contractors are essential for complex, deep, or utility-adjacent projects to ensure safety, compliance, and efficiency. Engaging experts minimizes risks and accelerates timelines, particularly for projects with stringent requirements.

Benefits of Professional Expertise

Professionals from Concrete Creations & Excavations bring specialized knowledge and advanced equipment to deliver precise, timely excavations, avoiding common novice errors. Their use of hydro digging protects underground utilities, while expertise in grading, trenching, and site preparation speeds up projects. Serving Northwest Arkansas, they minimize disruptions for both residential and commercial clients, ensuring projects stay on schedule.

Their transparent pricing and reliable scheduling maintain budget control, while their high-quality work guarantees long-lasting results, reducing future maintenance costs.

Choosing the Right Contractor

Selecting a licensed, reputable contractor with local expertise is critical, and Concrete Creations & Excavations stands out in Northwest Arkansas for its exceptional concrete and excavation services. Known for their work on pools, foundations, and driveways, they offer tailored solutions backed by strong community ties. Contact them at 479-341-5542 or visit https://www.concretecreationsandexcavations.com/ to request estimates and discuss project needs.

Their flexible operating hours, available Monday through Saturday from early morning to evening, accommodate diverse project schedules, ensuring accessibility and reliability.

Integrating Concrete and Excavation Services

Combining excavation with concrete services streamlines projects, as demonstrated by Concrete Creations & Excavations’ ability to transition seamlessly from digging to pouring driveways, patios, or foundations. This integrated approach eliminates delays caused by coordinating multiple contractors, making it ideal for projects like pools or structural foundations. Their offerings, including decorative stamped and stained concrete, enhance aesthetic outcomes while maintaining efficiency.

In conclusion, the time required to dig a hole with an excavator ranges from hours for small residential tasks to weeks for large commercial projects, influenced by the detailed factors explored here. For optimal efficiency, safety, and quality, partnering with a trusted excavation contractor like Concrete Creations & Excavations is highly recommended. Their expertise in both concrete and excavation services ensures seamless, high-quality results for projects throughout Northwest Arkansas, making them a go-to choice for all your digging needs.

Contact Us

Service Hours

Social Media

2025 | Concrete Creations & Excavations | Rights Reserved

Owned and Operated by JD's Concrete Creations LLC

Powered By: House Reno Profits

Blog > Concrete Creations & Excavations Article Library

Concrete Creations & Excavations Article Library

Welcome to the Concrete Creations & Excavations Blog Article Library, a valuable resource designed to connect homeowners like you with the world of concrete craftsmanship and innovation. Our blog serves as a hub for those seeking inspiration and information about the remarkable potential of concrete in transforming your living spaces. Whether you're planning a home improvement project, considering a renovation, or simply intrigued by the beauty of concrete, our library of articles is here to empower you with knowledge and insights. Join us on a journey of exploration as we unveil the incredible possibilities of concrete and showcase the exceptional creations that await you. At Concrete Creations & Excavations, we're not just a contractor; we're your partner in creating concrete masterpieces that enhance your home's beauty and functionality.

How long does it take to dig a hole with an excavator?

Digging a hole with an excavator is a critical task in construction, landscaping, and infrastructure projects, but the time required can vary significantly due to a multitude of influencing factors. Variables such as the size and depth of the hole, soil composition, type of excavator used, operator skill, and external conditions like weather all play pivotal roles in determining the duration of the task.

This comprehensive guide explores these elements in detail, providing actionable insights for homeowners, contractors, and project managers to plan their excavation projects effectively, while emphasizing the value of professional services like those offered by Concrete Creations & Excavations in Northwest Arkansas.

Excavators are powerful machines that transform digging from a labor-intensive process into a swift, mechanical operation, capable of completing in hours what might take days or weeks manually.

Understanding the interplay of equipment capabilities and site-specific challenges is essential for setting realistic timelines and budgets. Whether you're excavating for a residential pool, a commercial building foundation, or a utility trench, this article will help you anticipate the time required and make informed decisions to ensure project success.

Understanding Excavators

Excavators are robust, versatile machines designed for digging, lifting, and moving earth, featuring a boom, dipper, bucket, and rotating cab mounted on a base of tracks or wheels. Their efficiency stems from advanced hydraulic systems that enable precise, powerful movements across a wide range of terrains and materials.

Selecting the appropriate excavator type and size is crucial, as it directly influences digging speed, project feasibility, and overall efficiency, whether working in confined residential spaces or expansive commercial sites.

Types of Excavators and Their Capabilities

Crawler excavators, equipped with tracks for superior traction, are ideal for uneven or soft terrain, such as construction sites with loose soil or rocky ground. They excel in deep excavations, like those for building foundations, where their stability prevents tipping under heavy loads, allowing for rapid material removal in favorable conditions.

Wheeled excavators, designed for mobility on flat or paved surfaces, are well-suited for urban projects where quick repositioning between digging sites is necessary, reducing setup time and enhancing productivity.

Mini excavators, compact and weighing under ten tons, are perfect for residential tasks like digging utility trenches or small ponds, often completing these jobs in just a few hours due to their agility in tight spaces. Zero-tail-swing models minimize space requirements, making them ideal for backyards or areas near existing structures, preventing damage while maintaining efficiency.

Dragline excavators, used for large-scale projects like mining or deep pond excavation, utilize a long boom and drag bucket to move massive volumes of earth, though their complex setup can extend initial timelines. These are less common in standard construction but invaluable for large, deep holes.

Long-reach excavators, with arms extending significantly, are designed for digging in hard-to-access areas like wetlands or over obstacles, though their extended hydraulics may slightly slow cycle times due to the increased mechanical complexity.

Suction or vacuum excavators employ air or water jets for precise, non-destructive digging around utilities, prioritizing safety in sensitive areas, though this precision often comes at the cost of slower progress. Skid-steer excavators combine loader functionality with digging attachments, offering versatility for projects requiring both excavation and material spreading, making them ideal for multi-task sites.

Hydraulic shovels, built for heavy-duty tasks like mining, provide exceptional digging force but may operate more slowly in confined spaces compared to standard excavators. Short swing radius excavators reduce tail swing, enabling efficient work near walls, fences, or traffic, which speeds up urban digging by minimizing the need for constant repositioning.

Each excavator type’s capabilities, from bucket capacity to engine power, directly affect how quickly a hole can be dug, underscoring the importance of matching the machine to the project’s specific requirements.

How Excavator Size Influences Digging Speed

Mini excavators, lightweight and highly maneuverable, are designed for small holes, such as those for landscaping features or residential utility lines, completing these tasks in a few hours due to their quick cycle times in confined spaces.

They are ideal for homeowner projects where space is limited, efficiently handling moderate earth volumes daily. Mid-sized excavators, typically in the medium-weight range, enhance efficiency for commercial tasks, capable of moving larger quantities of material daily and reducing the number of passes needed for medium-sized holes, significantly shortening project timelines.

Large excavators, built for major digs like expansive foundation pits or commercial site preparations, can complete excavation over several days, including ancillary tasks like debris removal or site leveling.

Their sizable buckets allow for high output, but they require more fuel and skilled operators to maximize efficiency. The size of the excavator impacts cycle time; smaller machines complete scoops quickly due to their compact design, while larger ones take longer per cycle because of their greater reach and load capacity. Advanced hydraulic systems in newer models minimize delays by enabling faster boom and bucket movements.

Operator familiarity with the excavator’s size is critical; inexperienced operators may struggle with larger machines, leading to slower progress, while skilled operators can optimize movements to achieve faster completion times. Terrain compatibility also plays a role—compact excavators perform best in soft, confined areas, while larger models excel in open, hard ground excavations, where their power can be fully utilized.

Factors Affecting Digging Time

Numerous factors converge to determine how long it takes to dig a hole with an excavator, encompassing natural site characteristics, equipment performance, operator expertise, and external conditions.

Soil composition can drastically alter timelines, while weather and site accessibility introduce variables that can delay progress. Thorough pre-site assessments and strategic planning are essential to minimize these challenges and keep projects on track.

Soil Conditions and Their Impact

Loamy or sandy soils are ideal for rapid digging, allowing excavators to move through material quickly, particularly for linear tasks like trenches. These loose soils fill buckets efficiently, reducing cycle times and enabling faster progress.

Clay-heavy soils, however, are dense and sticky, resisting bucket penetration and requiring slower operations or specialized attachments like toothed buckets, which can significantly extend daily work durations. Rocky terrains pose another challenge, often necessitating hydraulic breakers to fragment material before removal, adding hours to the process.

The presence of groundwater complicates excavations, requiring dewatering pumps that halt digging for setup and ongoing management, potentially extending deep hole projects by days.

Soil testing through borings or geotechnical surveys can predict these issues, guiding the selection of appropriate equipment and attachments to mitigate delays. Particle size also influences efficiency; finer soils compact less, speeding up digging but potentially compromising wall stability, which may require additional stabilization measures.

Hole Size and Depth Considerations

Shallow holes, such as those for landscaping features or shallow utility lines, can often be completed in a matter of hours, especially with compact excavators designed for quick work in small areas.

Deeper excavations, particularly those exceeding significant depths, require shoring or sloping to prevent collapses, which can stretch timelines into weeks due to the need for careful, staged digging.

Calculating the volume of material to be removed is critical for estimating time—a modestly sized hole might be completed in a single day with a mid-sized excavator under good conditions.

Wider holes necessitate more passes, increasing the time required, though strategic sectional digging can optimize the process by focusing on smaller, manageable areas.

Complex hole shapes, such as those for irregularly designed pools, demand greater precision, adding time compared to straightforward rectangular excavations like those for building foundations.

Operator Experience and Machine Efficiency

Experienced operators significantly enhance productivity, maximizing material movement through efficient loading, swinging, and dumping techniques.

Their ability to minimize idle time and optimize machine movements can substantially reduce project durations. In contrast, inexperienced operators may double timelines by using suboptimal angles, requiring frequent corrections, or mismanaging equipment settings.

Regular maintenance of the excavator ensures peak performance; issues like clogged filters, worn components, or low hydraulic fluid can slow cycle times noticeably, leading to delays. The layout of the site also affects efficiency—larger swing angles increase loading time, so careful planning to position the machine and spoil piles effectively can streamline operations. Training specific to the excavator model used enhances speed, transforming potentially lengthy jobs into quicker completions.

Weather and Site Accessibility

Adverse weather, particularly heavy rain, can transform sites into muddy quagmires, slowing machinery and necessitating drying periods that may delay work by days. Extreme temperatures, such as cold weather, can affect hydraulic systems by thickening fluids and reducing operational speed.

Site accessibility is another critical factor; narrow or obstructed paths limit the size of the excavator that can be used, often requiring additional manual preparation that extends timelines.

Urban environments with obstacles like overhead power lines or underground utilities demand cautious, slower digging to avoid damage, while remote sites may increase transport time for heavy equipment. Scheduling excavations during favorable seasons, such as avoiding peak rainy periods, helps maintain consistent progress and avoid weather-related setbacks.

Average Timelines for Common Excavation Projects

Establishing timelines for common excavation projects provides valuable benchmarks for setting expectations, with residential tasks typically faster than commercial ones due to differences in scale and complexity. Linear excavations like utility trenches can progress rapidly, while foundation digs vary depending on the structure’s size and site conditions.

Residential Projects: Pools and Foundations

Excavating a hole for a backyard pool, typically of moderate size, generally takes a few days, including time for shaping the hole and preparing for drainage systems. Foundation excavations for standard homes can range from a single day for simple slabs to a week for basements, which require deeper digging and additional inspections.

Soil stability significantly influences timelines; sandy soils allow for faster progress, while clay-heavy sites demand extra stabilization efforts, slowing the process.

Smaller residential projects, such as excavations for home additions or detached garages, may be completed quickly, often in a day, though delays from permitting or unexpected site conditions can extend timelines. Professional excavation contractors like Concrete Creations & Excavations enhance efficiency with advanced techniques, such as hydro digging, which ensures safety around utilities and minimizes disruptions.

Commercial and Infrastructure Digging

Commercial site preparations, such as those for building pads or large foundations, typically span one to two weeks, depending on the area and depth of the excavation. Infrastructure projects, like road bases or expansive pits for utilities, can take significantly longer, particularly when regulatory inspections or environmental considerations require phased approaches.

Deploying multiple excavators can reduce timelines by allowing simultaneous work on different sections, though this increases coordination demands.

Concrete companies that integrate excavation with subsequent tasks, like pouring foundations, can streamline overall project timelines by eliminating delays between contractors.

Landscaping and Utility Trenches

Trenching for utilities, such as irrigation lines or electrical conduits, achieves high hourly progress rates, often completing long runs in a single day with narrow buckets designed for precision. Landscaping features, like ponds or tree planting pits, may take only hours individually, but projects involving multiple features can accumulate to several days.

Hydro excavation methods, while slower, are often used for utility trenches to prevent damage to existing infrastructure, prioritizing safety over speed.

Comprehensive yard redesigns that include grading or leveling alongside digging may span several days, with interruptions from inclement weather being a common challenge.

Safety Considerations in Excavation

Safety is paramount in excavation projects to prevent accidents, with cave-ins being a primary concern that requires proactive measures. Regular inspections and the use of protective systems are mandatory for deeper excavations to ensure worker safety and project continuity.

Preventing Cave-Ins and Falls

Sloping trench walls at appropriate angles or installing shoring systems, such as trench boxes, prevents collapses, particularly in excavations exceeding shallow depths.

Providing safe entry and exit points, like ladders placed at regular intervals, ensures workers can evacuate quickly in emergencies. Keeping spoil piles and heavy equipment away from excavation edges avoids overloading, which could trigger collapses or falls.

Daily monitoring for signs of instability, such as cracks or water accumulation, halts work if conditions are unsafe, preventing accidents that could delay projects significantly.

Atmospheric and Utility Hazards

Testing for hazardous gases in confined or deep excavations is critical, using monitors to check oxygen levels and detect toxins, with ventilation systems employed if conditions are unsafe. Identifying underground utilities through services like 811 calls prevents accidental strikes, which could lead to dangerous gas leaks or electrical hazards.

Hydro excavation is often used near marked utility lines to minimize risks, requiring careful, slower digging within close proximity.Water accumulation from rain or groundwater increases slip and collapse risks, necessitating pumping systems to maintain a safe working environment.

Personal Protective Equipment and Training

Workers must wear appropriate gear, including hard hats, gloves, steel-toed boots, and high-visibility vests, to protect against falling debris and ensure visibility on busy sites. Comprehensive training on excavator operation, site hazards, and emergency procedures reduces the likelihood of accidents, minimizing delays. High-visibility barriers and signage cordon off excavation zones, enhancing safety for both workers and passersby.

Ongoing education about soil types, weather impacts, and equipment safety fosters a culture of vigilance, extending project timelines slightly but saving significant costs by avoiding accidents.

Costs Involved in Digging with an Excavator

Budgeting for an excavation project involves accounting for equipment rentals, labor, and additional expenses, with costs varying based on the excavator’s size and project scope. Operator fees and site-specific requirements further influence the total budget, making cost estimation a critical planning step.

Rental and Operational Expenses

Mini excavators are available for short-term rentals at relatively affordable rates, suitable for small residential projects, while larger models command higher daily costs, particularly for commercial or infrastructure digs.

Transporting excavators to the site adds to expenses, especially for remote locations where logistics are complex. Maintenance packages, often included in rental agreements, ensure equipment reliability, preventing costly downtime due to mechanical issues.

Fuel consumption is a significant factor, with mid-sized excavators using substantial amounts hourly, which must be factored into budgets for extended projects.

Project-Specific Costs

Permitting and regulatory inspections can add to costs, varying by project size and location. Disposing of excavated material incurs fees based on volume, particularly for projects requiring off-site hauling. Specialized attachments, such as hydraulic breakers for rocky soils, increase rental costs, impacting the overall budget. Small excavations may have modest total costs, while large-scale projects can escalate significantly due to cumulative expenses.

Engaging excavation services near you, like those provided by Concrete Creations & Excavations, often bundles these costs efficiently, leveraging expertise to optimize spending.

Value of Professional Services

Hiring professional excavation contractors eliminates the complexities of managing rentals and logistics, with firms like Concrete Creations & Excavations offering comprehensive solutions at competitive rates. With extensive experience in Northwest Arkansas, they ensure efficient, cost-effective excavations tailored to local conditions. Integrating concrete services post-excavation, such as pouring foundations or driveways, reduces costs by streamlining contractor coordination.

When to Hire a Professional Excavation Contractor

While DIY excavation may be feasible for small, shallow holes, professional contractors are essential for complex, deep, or utility-adjacent projects to ensure safety, compliance, and efficiency. Engaging experts minimizes risks and accelerates timelines, particularly for projects with stringent requirements.

Benefits of Professional Expertise

Professionals from Concrete Creations & Excavations bring specialized knowledge and advanced equipment to deliver precise, timely excavations, avoiding common novice errors. Their use of hydro digging protects underground utilities, while expertise in grading, trenching, and site preparation speeds up projects. Serving Northwest Arkansas, they minimize disruptions for both residential and commercial clients, ensuring projects stay on schedule.

Their transparent pricing and reliable scheduling maintain budget control, while their high-quality work guarantees long-lasting results, reducing future maintenance costs.

Choosing the Right Contractor

Selecting a licensed, reputable contractor with local expertise is critical, and Concrete Creations & Excavations stands out in Northwest Arkansas for its exceptional concrete and excavation services. Known for their work on pools, foundations, and driveways, they offer tailored solutions backed by strong community ties. Contact them at 479-341-5542 or visit https://www.concretecreationsandexcavations.com/ to request estimates and discuss project needs.

Their flexible operating hours, available Monday through Saturday from early morning to evening, accommodate diverse project schedules, ensuring accessibility and reliability.

Integrating Concrete and Excavation Services

Combining excavation with concrete services streamlines projects, as demonstrated by Concrete Creations & Excavations’ ability to transition seamlessly from digging to pouring driveways, patios, or foundations. This integrated approach eliminates delays caused by coordinating multiple contractors, making it ideal for projects like pools or structural foundations. Their offerings, including decorative stamped and stained concrete, enhance aesthetic outcomes while maintaining efficiency.

In conclusion, the time required to dig a hole with an excavator ranges from hours for small residential tasks to weeks for large commercial projects, influenced by the detailed factors explored here. For optimal efficiency, safety, and quality, partnering with a trusted excavation contractor like Concrete Creations & Excavations is highly recommended. Their expertise in both concrete and excavation services ensures seamless, high-quality results for projects throughout Northwest Arkansas, making them a go-to choice for all your digging needs.

Contact Us

479-341-5542

Centerton, AR, 72719

Service Hours

Mon-Sat: 7am - 7pm

Sun: OFF

Social Media